Averaging Pitot Tube Pdf Editor

An averaging pitot tube flow run is easily configured with ModWorX® Pro software provided free of charge with all Scanner 2000 purchases. An averaging pitot tube measures flow by averaging the pressure at various ports along the length of a probe. A typical meter. Meter or edit the parameters of.

Point velocity measurements conducted by traversing a Pitot tube across the cross section of a flow conduit continue to be the standard practice for evaluating the accuracy of continuous flow-monitoring devices. Such velocity traverses were conducted in the exhaust duct of a reduced-scale analog of a stationary source, and mean flow velocity was computed using several common integration techniques. Sources of random and systematic measurement uncertainty were identified and applied in the uncertainty analysis. When applicable, the minimum requirements of the standard test methods were used to estimate measurement uncertainty due to random sources. Estimates of the systematic measurement uncertainty due to discretized measurements of the asymmetric flow field were determined by simulating point velocity traverse measurements in a flow distribution generated using computational fluid dynamics. For the evaluated flow system, estimates of relative expanded uncertainty for the mean flow velocity ranged from ±1.4% to ±9.3% and depended on the number of measurement locations and the method of integration. Implications: Accurate flow measurements in smokestacks are critical for quantifying the levels of greenhouse gas emissions from fossil-fuel-burning power plants, the largest emitters of carbon dioxide.

A systematic uncertainty analysis is necessary to evaluate the accuracy of these measurements. This study demonstrates such an analysis and its application to identify specific measurement components and procedures needing focused attention to improve the accuracy of mean flow velocity measurements in smokestacks. Introduction In 2011, fossil-fuel-consuming stationary sources such as electric power plants accounted for 41% of carbon dioxide emissions in the United States (U.S. Environmental Protection Agency [EPA], 2013). This was the largest contribution by any sector of greenhouse gas (GHG) emission sources. Accurate flow measurements are critical for quantifying the levels of GHGs and other pollutants emitted from the smokestacks of power plants burning fossil fuels. The mass flow is currently measured using industrial continuous emissions monitoring systems (CEMS) installed in the smokestacks.

The CEMS instrumentation determines the emission rates of regulated pollutants by multiplying the measured pollutant concentration level by the total measured flow. Large uncertainties in either measurement result in greater uncertainty in reported total emissions. Emission determinations having large uncertainty make it difficult to judge whether emission targets are being met locally—at the source, within a region, and ultimately throughout the world. To accurately assess the effectiveness of GHG mitigation strategies, GHG measurements must be traceable to reliable standards at sufficiently low uncertainties. It is standard practice to conduct multiple Pitot traverses of point velocity measurements to evaluate the accuracy of the continuous flow-monitoring devices. This study demonstrates how the exhaust duct of the Large Fire Research Laboratory (LFRL) at the National Institute of Standards and Technology (NIST) was used to assess the uncertainty of mean flow velocity measurements made by Pitot traversing techniques.

The NIST LFRL routinely conducts large-scale fire experiments and measures the flow of effluents in its exhaust duct, much like CEMS measurements at a stationary source. The exhaust duct velocity is measured with an averaging Pitot tube, Annubar. ( Certain commercial entities, equipment, or materials are identified in this document in order to describe an experimental procedure or concept adequately. Such identification does not imply recommendation or endorsement by the National Institute of Standards and Technology, nor does it imply that the entities, materials, or equipment are necessarily the best available for the purpose.) The device is not capable of providing velocity distribution information, but provides an integrated average of the distribution of differential pressure induced along the device by the flow. In this work, the Annubar measurement was conducted alongside independent velocity measurements made with S-type Pitot probes, one of which was calibrated in the NIST wind tunnel. The S probes were used to conduct velocity traverse experiments and measure the velocity profile in the exhaust duct along two orthogonal chords spanning the duct diameter. In the present comparison, a natural-gas burner under steady-state conditions was used as the emissions source.

To establish a measurement baseline, velocity traverses were first conducted without the natural-gas burner (i.e., ambient flow conditions). Subsequent measurements were conducted with the burner for various inlet conditions (e.g., heat input, burner location, and flow magnitude) to simulate the range of normal operational conditions. The velocity field was also calculated using computational fluid dynamics (CFD) and compared to the velocity profiles measured by traversing the S probes. The CFD calculations modeled only the ambient flow conditions. The following sections present a description of the experimental and numerical procedures and discussion of the results.

Facility The NIST LFRL is a large-scale facility for the study of a broad range of fire phenomena, including the burning of materials, products, furnished rooms, and portions of buildings ( Bryant, R.A., T.J. Ohlemiller, E.L. Maranghides, and G.W. The NIST 3 Megawatt Quantitative Heat Release Rate Facility.

NIST Special Publication 1007. Gaithersburg, MD: National Institute of Standards and Technology.

The primary measurement of the facility is the transient heat release or the amount of power generated from the burning of materials. At the time of this study, the facility was equipped with three exhaust hoods shown in, including a large hood with dimensions 9 m × 12 m, a medium hood with dimensions 6 m × 6 m, and a small hood with dimensions 3 m × 3 m.

The largest hood can remove the effluent of fires at a rate of up to 2690 m 3/min (95,000 ft 3/min). This allows for the removal of effluents for fires with heat release of up to 10 MW. Sustained periods of burning were possible for heat release of 3 MW or less. The exhaust duct, shown in Figure 1b, runs horizontally along the roof of the facility with a series of turns. The labels 1 and 2 in Figure 1b show the locations where effluents from the large hood and medium hood, respectively, enter the exhaust duct.

The inner diameter, D, of the exhaust duct at the velocity traverse cross section was 1.503 m ± 0.012 m. This cross section, shown in Figure 1b, was located 9.2 D downstream of the 180° bend and 2.9 D upstream of the Annubar.

The LFRL is currently in the process of a major construction remodel and expansion. It will reopen as the National Fire Research Laboratory (NFRL), equipped with an additional hood and floor space to accommodate fires with heat release rates as large as 20 MW. With the added capacity, the new facility will be closer to the low end of heat input capacity for small gas- or oil-fired stationary combustion sources. Therefore, in addition to its contribution to fire research, it can be used as a near-industrial-scale surrogate for improving the measurement science of emissions from stationary sources. Procedures Two series of experiments, Series 1 and Series 2, were conducted to measure the velocity distribution in the exhaust duct.

Velocity profiles were measured on two perpendicular chords of the duct cross section. In Series 1, traverses were conducted with a measurement spacing of 2.54 cm in order to fully characterize the velocity profile. The traverses were along a single chord (either chord 1 or chord 2) using a single S probe that was calibrated in the NIST wind tunnel ( Shinder, I.I., J.C. Crowley, B.J. Filla, and R.M.

Improvements to NIST’s Air Speed Calibration Service. Paper presented at FLOMEKO, Paris, France, September.; Yeh, T.T., and J.M.

Airspeed Calibration Service. NIST SP 250-79. Gaithersburg, MD: National Institute of Standards and Technology. Point velocity measurements were conducted according to the procedures defined by EPA Method 2G ( U.S.

Environmental Protection Agency. Determination of Stack Gas Velocity and Volumetric Flow Rate with Two-Dimensional Probes. EPA Method 2G. Washington, DC: U.S.

Environmental Protection Agency. The procedures account for the angle of the flow in the plane perpendicular to the traverse line—the yaw angle—and therefore determine the near-axial velocity.

Series 2 experiments were conducted by an independent stack testing company (STC), using two S probes; one on each chord. Measurement procedures followed EPA Method 2 (EPA, 2000a) with 48 total traverse points (24 per chord) or EPA Method 2G with 40 total traverse points (20 per chord). The choice of method depended on the amount of off-axis flow. Traverse points for this series corresponded to EPA Method 1 ( U.S. Environmental Protection Agency.

Sample and Velocity Traverses for Stationary Sources. EPA Method 1.

Washington, DC: U.S. Environmental Protection Agency. ) centroid of equal area positions. A schematic of the cross section for the velocity traverse measurements is shown in.

The figure shows that the two chords were nearly orthogonal with the chord 1 traverse starting at θ = 322°± 1° and the chord 2 traverse starting at θ = 50°± 1°. Simultaneous velocity measurements were also made using the Annubar flowmeter. The Annubar serves as the LFRL’s continuous flow-monitoring device. It was mounted in a vertical orientation and positioned 2.9 diameters downstream of the velocity traverse plane.

Mean flow velocity measurements were recorded from the Annubar for each velocity traverse experiment. The Annubar was not disturbed during a series of experiments or between series. Therefore, the measurement provided a reference parameter for changes in experimental conditions.

Computational Methods The computations performed here used the commercial solver CFD-ACE. The CFD model solves the steady, three-dimensional Navier–Stokes and continuity equations using the finite-volume method. In this method, fluxes of momentum and mass are conserved on finite volumes rather than on the differential volumes of the governing partial differential equations (i.e., Navier–Stokes and continuity equations).

Consequently, on each finite volume in the computational domain, the partial differential equations are converted into a coupled set of nonlinear algebraic equations. Iterative techniques are used to solve this system of algebraic equations over the entire computational domain. Iterations are continued until the residuals (i.e., error in the numerical solutions) are reduced by six orders of magnitude. The computational domain used to model the inlet section at the large hood and the remaining exhaust ducting consisted of 822,835 finite volumes. The mesh, shown in, was composed of 605 axial grid cells with 1312 grid faces in each cross section of the flow. This resulted in 793,760 finite volumes from the inlet to the outlet of the main duct flow.

The remaining finite volumes were in the section of the duct connected to the medium hood. Although the mesh included this section that connects to the medium hood, the large hood was the source for flow for all of the CFD simulations. Computations were also performed using coarser grids, with no discernible difference in velocity profiles, thereby establishing the grid independence of the solution. The inlet flow boundary condition was set equal to the experimentally measured mass flow, while at the exit the atmospheric pressure conditions were specified.

The flow computations were performed assuming the gas was both incompressible and isothermal with a constant temperature of T = 297 K. In the experiment, atmospheric pressure conditions exist at the inlet of the duct since the exhaust fans are at the far end of the duct. This is opposite of the inlet conditions defined in the CFD computation; however, the computation models the same pressure gradient along the duct as determined from the experiment. Flow profile is established by the pressure gradient for incompressible flow. Turbulence was modeled using the Kato–Launder k- model since it accounts for regions of flow stagnation. ( Kato, M., and B.E.

The modelling of turbulent flow around stationary and vibrating square cylinders. Paper presented at Ninth Symposium on Turbulent Shear Flows, Kyoto, Japan, August. ) The inlet turbulence intensity was taken to be 2%. As shown in, the cross section of the mesh was clustered near the wall to account for the steep velocity gradients present in the boundary layer. The fine meshing near the wall ensures the validity of the wall functions used in the turbulent model. Velocity distribution The flow traverses were conducted after steady-state conditions were achieved in the exhaust duct.

Each velocity probe was configured with a Type K thermocouple (shielded) for gas temperature measurements and with a digital inclinometer to measure the yaw angle. The temperature inside the exhaust duct was less than 400 K (127°C) for a heat input of 2 MW.

For a heated experiment, the range of temperatures along a profile generally varied within 15 K or less. The temperature was lowest near the probe access ports, due to fresh air leaking into the duct, and highest near the center of the duct. Yaw angles were the greatest near the walls, especially the wall containing the probe access port. Yaw angles at the walls were less than 15°. Beginning with ambient flow conditions, Series 1 velocity traverses were performed for the large exhaust hood on a single chord with a uniform spacing of 2.54 cm between each traverse point.

Shows the near axial velocity profile across chords 1 and 2, respectively. The near axial velocity measured by the probes is calculated by 1 where is the calibration coefficient, is the measured yaw angle, is the differential pressure measured across the S probe ports, is the static pressure, is the thermocouple temperature measurement, is the universal gas constant, is the molar mass (wet basis), is the radial position along a traverse chord (with radius ), and is the circumferential position of the chord. Differential pressure, temperature, and yaw angle all depend on radial and circumferential position. The near axial velocity ( v z) is normalized by the corresponding Annubar velocity, v ann, to facilitate a straightforward comparison of the velocity profile over a range of different conditions. On chord 1, the velocity profile is relatively uniform in the center region of the duct. On chord 2, the profile is skewed so that the velocity peaks just prior to the boundary layer on the far side of the exhaust duct.

Velocity traverses were repeated for conditions of heated flows with the natural-gas burner (1 MW) placed at the southwest (SW) quadrant of the footprint of the large exhaust hood. The profiles are similar to the ambient flow profiles, suggesting that the addition of heat to the flow does not produce significant changes in the general characteristics of the velocity distribution for the large exhaust hood. A least-squares polynomial fit was generated for the data to represent the general characteristics of the velocity distribution for the large hood. The fit is plotted in for each chord.

An uncertainty analysis was performed to estimate the combined uncertainty of the point velocity measurements. Assuming that the input measurements for were mutually independent, the following equation was applied to estimate the combined uncertainty for the gas velocity: 2 The standard uncertainty, u(x i), for each input measurement, x i, used to compute the gas velocity ( y = v z), is listed in. The nondimensional sensitivity coefficient, given as. 3 is also listed in the table to reflect the weight applied to the standard uncertainty of each component. Estimates of the relative expanded uncertainty (twice the relative standard uncertainty for a 95% confidence interval) of the point velocity measurements were ±0.01 for Series 1 measurements. Mean flow velocity from the Annubar measurement was derived from an equation similar to, but without the correction for flow angle.

An uncertainty propagation of the Annubar measurements resulted in an initial relative expanded uncertainty estimate of ±0.015. This estimate was based on the manufacturer’s accuracy and precision estimates for a fully developed flow distribution. Velocity traverses for Series 2 were conducted with two S probes: one on chord 1 and one on chord 2. In order to conduct a greater number of repeat experiments while expanding the range of experimental conditions, the point velocity measurements were conducted at centroid of equal area (CEA) locations (EPA Method 1) instead of at a uniform spacing along a chord. EPA Method 2 or Method 2G was followed depending on the amount of off-axis flow. Coarse surveys were first conducted to assess the off-axis flow.

When the estimated change in average velocity due to off-axis flow was less than 0.5%, the velocity surveys were conducted following Method 2, using a total of 48 centroid of equal area positions (24 per chord, 12 per radius). Otherwise, Method 2G was followed to measure yaw angle and the near-axial velocity for a total of 40 centroid of equal area positions (20 per chord, 10 per radius). Series 2 measurement uncertainty was based on uncertainty estimates quoted from EPA standard test methods (). In the absence of an estimate for a component measurement uncertainty in the EPA standards, uncertainty estimates from the ASTM D 3154 ( ASTM International. Standard Test Method for Average Velocity in a Duct (Pitot Tube Method). West Conshohocken, PA: ASTM International. ) standard were applied.

The relative expanded uncertainty for Series 2 point velocity measurements ranged from ±0.032 to ±0.107, with a nominal value of ±0.060. When compared to Series 1, the larger uncertainty for Series 2 point velocity measurements was mostly due to the larger uncertainty in the S probe calibration coefficient, C p, which contributes more than 85% to the combined uncertainty. The quoted uncertainty requirement for the differential pressure measurement was a percentage of the instrument full-scale measurement. At low flow velocities, this resulted in larger uncertainties for the differential pressure measurement and therefore a larger contribution to the combined uncertainty. Like Series 1, Series 2 experiments began with ambient flow conditions in the large exhaust hood. Off-axis flow was not significant for the ambient flow and it was not significant for the heated flow conditions when the burner was located in the southwest quadrant of the exhaust hood.

Ambient-flow velocity profiles are shown in. Each velocity measured at the probe is plotted normalized by the average velocity measured at the Annubar.

The Annubar mean flow velocity is computed for the duration of the traverse. The velocity profiles are consistent with those from Series 1 for the ambient flow conditions. Least-squares polynomial fits are plotted for the repeat measurements. In the center region of the flow, the velocity ratio moves closer to unity with increasing flow magnitude.

When 1 MW and 2 MW of thermal energy were added to the flow, the shapes of the velocity profiles remained consistent with the ambient flow profiles (). Moving the natural-gas burner from the southwest quadrant to the center of the exhaust duct did not have a significant effect on the velocity profiles, but the amount of off-axis flow increased. Hence, Method 2G was followed for experiments with the natural-gas burner centered under the exhaust hood. CFD simulation The output from the CFD model includes three-dimensional velocity vectors in each control volume of the grid. This facilitates comparison between the predicted and measured velocity profiles along chord 1 (at θ = 322°) and chord 2 (at θ = 50°). CFD results were computed for the case of the ambient flow entering the large hood. The computed velocity profiles are shown in, along with the experimental data.

The CFD velocity is scaled so that the average CFD velocity equals the average measured velocity. Both the CFD results and the measured profiles exhibited similar trends. On chord 1, both the CFD and measured profiles are nearly symmetric. In contrast, the measured profile is flat at the center of the duct while the CFD profile reaches a local minimum near the center of the duct. On chord 2, both the CFD and measured profiles are skewed so that the velocity peaks on the far side just prior to the boundary layer. However, the CFD predicts a more pronounced velocity peak than the measurements.

Although velocity differences were as large as 10%, the CFD is in good qualitative agreement (i.e., similar velocity profile) with the measurements. The goal of future work will be to improve the CFD predictions by using more sophisticated turbulence models. The CFD model can also be used to visualize advanced flow features (e.g., recirculation zones, swirl decay, velocity profile development) that otherwise would require specialized experimental facilities. In the current work, the CFD predicted a recirculation zone just downstream of the 180° bend at z = 0 (see ). This flow separation induces the skewed flow distribution on chord 2.

The asymmetry in the flow is better observed from the slice view of the axial velocity, shown in, at the plane of the velocity traverse, z = 9.2 D downstream of the bend. The slice view demonstrates that the flow is not fully developed at the traversing plane and is skewed toward one hemisphere, which is consistent with the measurements.

If not accounted for, this lack of symmetry in the flow can induce systematic error or bias in the mean flow velocity measurement, as demonstrated by Salami (1972). Consequently, the area-averaged velocity over the cross section cannot be completely determined by measuring the velocity at only two chords (i.e., chords 1 and 2). A demonstration of how the velocity distribution predicted by the CFD can be used to estimate the potential for systematic error follows.

Mean flow velocity calculation With the knowledge of the distribution of axial velocity and gas density,, at any cross section inside a circular conduit, the actual mean flow velocity in the conduit may be determined from the following formula: 4 Experimental measurements will have a finite number of sampling locations in the cross section due to limitations such as probe size, physical access, and the time available to conduct the measurements. Therefore, the mean flow velocity must be estimated from a numerical integration of a discrete set of measurements distributed throughout the cross section. This estimate of mean flow velocity is then computed by the following formula: 5 where is a weighting factor that determines the numerical integration scheme, M is the number of sample locations along a radii, and 2 N is the number of radii (twice the number of chords, N). The angular spacing between the 2 N radii is uniform so that each radius has a corresponding radius separated by 180 degrees, which together comprise a chord.

In this work was evaluated using the following numerical integration schemes: (1) trapezoidal rule, (2) Simpson’s rule, (3) centroids of equal area, and (4) Gauss–Legendre quadrature. Each of these numerical methods is computed by selecting the appropriate mathematical expression for ( Dahlquist, G., and A. Numerical Methods. Englewood Cliffs, NJ: Prentice Hall.; Jain, M.K., S.R.K.

Iyengar, and R.K. Numerical Methods for Scientific and Engineering Computation. New York, NY: Halsted Press. The density ( ) and the axial velocity ( ) are evaluated at locations and consistent with the integration method.

When uniform density can be assumed and the sampling locations are chosen for centroids of equal area, as defined in EPA Method 1, reduces to an arithmetic average of the velocities. Discretization error estimate The difference between the estimated mean flow velocity,, and the actual mean flow velocity,, is the discretization error.

The CFD generated velocity slice in was demonstrated as a good qualitative estimate of the flow distribution. The total mass flow rate was defined as an inlet boundary condition for the CFD simulation and therefore can be used to define the actual mean flow velocity at the cross section. More than 59,000 data points (240 radii with 249 points/radii) were generated by interpolating the additional data using the computed grid points from the CFD slice: enough to approach an analytically determined distribution of flow velocity for the cross section. This approach is analogous to an effort by Brooks and Williams to estimate the “mapping error” of velocity traverses ( Brooks, E. Install Windows 7 Portege M400. F., and R.L. Flow and Gas Sampling Manual. EPA-600/2-76-203, Washington, DC: U.S. Environmental Protection Agency.

They used a grid of 525 point velocity measurements from a rectangular cross section and curve fitting techniques to generate a velocity distribution for interpolating flow velocity at desired locations. The CFD-generated velocity slice is therefore a useful tool to demonstrate the impact of the number of sampling locations on discretization error. Several studies have analyzed the effect of flow asymmetry on the accuracy of mean flow velocity techniques using point velocity measurements ( Frank, S., C. Heilmann, and H.E. Point-velocity methods for flow-rate measurements in asymmetric pipe flow. Flow Measurement and Instrumentation 7(3–4): 201– 9.

Doi: 10.1016/S0955-595-5,; Salami, 1972) or ultrasonic transit-time measurements ( Moore, P.I., G.J. Brown, and B.P. Ultrasonic transit-time flowmeters modelled with theoretical velocity profiles: Methodology. Measurement Science & Technology 11(12): 1802– 11.

Doi: 10.1088/0957-0233/11/12/321, ). Application of a computer to asymmetric flow measurement in circular pipes.

Transactions of the Institute of Measurement and Control 6(4): 197– 206. Doi: 10.113, as well as Moore, has generated analytical distributions of flow velocity that are similar to real asymmetric flow distributions such as those measured downstream of bends, orifices, or junctions. These flow distributions have the advantage of being integrated to an exact solution, making the computation of the actual mean flow velocity possible. A similar analysis is conducted in this study by replacing the analytical distribution with the flow distribution generated from the CFD simulation—a better approximation of the actual flow.

The estimate for relative discretization error is defined by the following formula: 6 where is the estimated mean flow velocity computed for a finite number of points from the CFD simulated flow and is the actual mean flow velocity for the same simulated flow. The simulated flow distribution was divided into 240 radii with 249 points/radii. Therefore, it is possible to study the effect of the flow asymmetry on the accuracy of mean flow velocity methods with respect to the number of traverse radii (or chords), traverse points per radius, and the orientation of the traverse radii. Demonstrates how the error in the estimated mean flow velocity depends on the circumferential position of the chord selected for the traverse as well as the number of chords selected. For this illustration, the EPA method of centroids of equal area with 24 total traverse positions was chosen.

In the case of only one traverse chord, the maximum potential of the relative error estimate, E d,max = E d max, was 0.024. Increasing the number of chords to two, reduced the maximum potential to 0.012. There are circumferential regions where the relative error is very close to zero. Traverse chords selected from these regions would reduce the potential for discretization error. In practice, limited physical access to these regions may only allow one to optimize chord selection to achieve better performance for mean flow velocity measurements. Estimates of mean flow velocity were computed for the CFD generated flow using for the four integration schemes.

The simulated traverse points were equally spaced along a radius when the trapezoid rule and Simpson’s rule were applied. For the EPA method, the simulated traverse points corresponded to centroid of equal area positions, in EPA Method 1. Similarly, traverse positions defined by the Gauss–Legendre method were used for this integration scheme. The maximum potential discretization error, E d,max, shown in, is summarized in for the four integration schemes, for configurations of 1, 2, and 4 chords ( N), and for up to 30 points per radius ( M). For the asymmetric flow profile considered in this study, the EPA and Gauss–Legendre integration schemes give the lowest potential for discretization error, especially for the range of total traverse locations used in practice. Both the trapezoid rule and Simpson’s rule integration schemes would require more than 100 equally spaced points per radius on 4 radii to ensure a relative maximum-potential discretization-error less than 0.02. Using EPA or Gauss–Legendre on 2 orthogonal chords, it is possible to reduce the potential relative error to 0.01 or less.

For this two chord configuration the optimum range of traverse points per radius is 8 to 15 for EPA and 3 to 9 for Gauss–Legendre. In practice the discretization error is a bias in the measurement and therefore contributes to the systematic measurement uncertainty. The discretization error computed from the CFD simulation provides a good estimate of the measurement bias. Due to the good qualitative agreement of the simulation and the experimental results, it is reasonable to assume that the actual mean flow velocity lies within the interval.

A rectangular distribution of possible values is further assumed to estimate the experimental uncertainty due to bias as. This estimate for uncertainty due to bias is used in the next section to estimate the combined measurement uncertainty. Mean flow velocity For the present study, the velocity survey was performed over two diametric chords, N = 2 (2 N = 4 radii), and the number of sample locations along each chord ranged from 12 to 60 (12 ≤ 2 M ≤ 60). Velocity surveys were conducted on a single chord, either chord 1 or chord 2, in Series 1. The procedures improved during Series 2, with the capability to conduct the velocity surveys on both chords, simultaneously. Mean flow velocity was computed as an arithmetic average of the local velocity measurements, following the procedures of EPA Method 2 and 2G. Numerical integrations based on the trapezoid rule, Simpson’s rule, and Gauss–Legendre quadrature, were also used to compute the mean flow velocity for comparison.

Mean flow velocity resulting from the different computation methods is displayed in for Series 1 experiments. The values are normalized by the mean flow velocity measured with the Annubar. For the flow distributions considered in this study, the four mean flow velocity computations agreed to within 2.6% (2 standard deviations). On average, the EPA centroid of equal area method gave the greatest estimate of mean flow velocity, while the trapezoid rule numerical integration gave the lowest estimate.

The same trend and the same level of agreement, 2.6%, were observed with the Series 2 results. The uncertainty of the mean flow velocity is defined in this work as a combination of the measurement uncertainty and an estimate, based on simulations, of the likelihood of achieving the true mean flow velocity. Thus, the uncertainty has a contribution from the combined uncertainty of the integration of the point measurements and the estimated bias due to the discretization of the flow field as defined by the chosen measurement sampling strategy: 7 The combined uncertainty of the integration,, is determined using an uncertainty propagation of measurement uncertainties as applied to. The uncertainty due to measurement bias is determined from estimates of maximum relative discretization error generated using the CFD simulation. Nominal estimates for uncertainty of the mean flow velocity are listed in. The estimates for the combined relative uncertainty of the integrations were on the order of 0.006 or less.

Measurements in Series 1 were conducted with instrumentation that surpassed the minimum requirements for measurement uncertainty as defined by the standard test methods (EPA and ASTM) and therefore had lower uncertainty estimates than Series 2 for the integrations. The estimates for uncertainty due to bias demonstrate how increasing the number of sampling points and the number of measurement chords help to reduce the bias. For example, increasing the measurement locations from 12 on 1 chord to 48 on 2 chords reduced the uncertainty due to bias by a factor of 2 or more when applying either the EPA or Gauss–Legendre methods. Both the S probe and Annubar infer flow velocity from a measurement of impact velocity.

Without an independent method of measurement for comparison (such as a tracer dilution measurement for volume flow rate or multipath acoustic for flow velocity), it is difficult to determine which of the four mean flow computation methods will generate the most accurate results. Since the centroid of equal area methods (EPA Methods 1, 2, and 2G) is a standard test method for the stack testing industry, these methods of computing mean flow velocity are considered here. For the flow distribution considered in this study, EPA procedures had the lowest estimate of combined uncertainty when compared across physical sampling schemes and integration methods of computing mean flow velocity.

The relative expanded uncertainty estimates were ±2.6% and ±1.4% for Series 1 and Series 2, respectively. A combination of lower component measurement uncertainty as demonstrated in Series 1 and an adequate number of sampling locations as demonstrated in Series 2 suggests that it is possible to reduce the expanded uncertainty to approximately ±1.0% for similar flow distributions using EPA Method 2 or Method 2G.

Mean flow velocity results from Series 1 and Series 2 are shown in. The values were each normalized by the mean flow velocity measured at the Annubar, which was unchanged between the series of experiments and therefore provided a reference to connect the results. The ratio is a correction factor or in situ calibration factor for the Annubar measurements. Results from Series 1 velocity traverses generated an 8% correction for the Annubar. The correction determined from Series 2 experiments ranged from 5% to 6%, and demonstrated a small dependence on the flow velocity.

This lower correction is consistent with the lower S probe calibration coefficients for Series 2 experiments. It is of value to note that Series 1 and Series 2 measurements used similar experimental methodologies, but differ, as Series 2 measurements were conducted by an independent testing group, using their own equipment, instrumentation, and instrument calibrations. Also it is worthy to note that Series 1 measurements were conducted on a single chord, either chord 1 or chord 2. In general, the correction factors determined from both sets of experiments agreed to within 4% when mean flow velocity was less than 25 m/sec.

Conclusion Determining mean flow velocity from point velocity measurements made by Pitot traversing techniques is the standard practice for evaluating the accuracy of continuous flow-monitoring devices in the smokestacks of fossil-fuel-burning stationary sources. An uncertainty analysis was conducted for mean flow velocity measurements in the exhaust duct of the NIST LFRL, which served as a surrogate stationary source.

The analysis included sources of random and systematic uncertainty. Asymmetry was identified in the duct flow that has the potential to induce systematic measurement uncertainty. The level of uncertainty will depend on the measurement strategy chosen. A CFD simulation of the flow distribution was in good qualitative agreement with the experimental results and therefore was used to estimate the systematic uncertainty induced by the flow asymmetry and choice of mean flow velocity integration scheme. The analysis, using the simulated flow distribution, showed that the centroid of equal area and Gauss–Legendre integrations schemes resulted in the lowest contribution to the systematic measurement uncertainty for the flow asymmetry considered. Using either of these schemes with point velocity measurements on two orthogonal chords, the maximum potential for discretization error can be reduced to 1.0% or less. The results of this study demonstrate how CFD simulations of real flows can be used to estimate as well as reduce the discretization error of mean flow velocity measurement techniques.

Two series of mean flow velocity measurements were conducted in the LFRL exhaust duct by two independent groups. The groups achieved agreement to within 4.0%, using similar experimental procedures, but independent instrumentation and instrument calibrations. The difference in the S probe calibration coefficients is a potential cause for the discrepancy between the results. Roland Metz Software. When considering the centroid of equal area integration scheme (EPA Methods 1, 2, and 2G), the uncertainty analysis for both series of measurements resulted in estimates of ±2.6% and ±1.4% for the expanded uncertainty of the mean flow velocity measurements.

It is possible to reduce the expanded uncertainty to ±1.0% or less for a similar flow distribution by using an adequate number of point velocity measurements and improved S probe calibrations. Acknowledgment The authors gratefully acknowledge the technical and engineering support provided by Marco Fernandez, Laurean DeLauter, Doris Rinehart, and Anthony Chakalis and data acquisition support provided by Artur Chernovsky. They are grateful for calibration services provided by Iosif Shinder and the Fluid Metrology Group, and for technical guidance provided by Anthony Hamins, Jiann Yang, and Michael Moldover.

Research support by the NIST Office of Special Programs—Greenhouse Gas and Climate Science Measurements, James Whetstone Program Manager—is gratefully acknowledged. Uncertainty budget for Series 1 point velocity measurements Measurement component, x i Value Relative standard uncertainty, u(x i)/x i Nondimensional sensitivity coefficient, s i Percent contribution,% Probe coefficient, C p 0.818 0.0048 1.0 86.7 Probe yaw, (deg) 2.49 0.0201 0.002 0 Probe differential pressure, Δ p (Pa) 110.38 0.0008 0.5 0.5 Gas temperature, T (K) 296 0.0037 0.5 12.8 Duct static pressure, P s (Pa) 100722 0.0001 −0.5 0 Gas molecular weight, M wet (kg/kmol) 28.297 0.0001 −0.5 0 Near axial velocity, v z (m/sec) 11.28 0.0052 (0.0104) Standard uncertainty (Expanded uncertainty).

A positive displacement flowmeter of the oval gear type. Fluid forces the meshed gears to rotate; each rotation corresponds to a fixed volume of fluid. Counting the revolutions totalizes volume, and the rate is proportional to flow. An oval gear meter is a positive displacement meter that uses two or more oblong gears configured to rotate at right angles to one another, forming a T shape. Such a meter has two sides, which can be called A and B.

No fluid passes through the center of the meter, where the teeth of the two gears always mesh. On one side of the meter (A), the teeth of the gears close off the fluid flow because the elongated gear on side A is protruding into the measurement chamber, while on the other side of the meter (B), a cavity holds a fixed volume of fluid in a measurement chamber. As the fluid pushes the gears, it rotates them, allowing the fluid in the measurement chamber on side B to be released into the outlet port. Meanwhile, fluid entering the inlet port will be driven into the measurement chamber of side A, which is now open. The teeth on side B will now close off the fluid from entering side B. This cycle continues as the gears rotate and fluid is metered through alternating measurement chambers.

Permanent magnets in the rotating gears can transmit a signal to an electric reed switch or current transducer for flow measurement. Though claims for high performance are made, they are generally not as precise as the sliding vane design.

Gear meter [ ] Gear meters differ from oval gear meters in that the measurement chambers are made up of the gaps between the teeth of the gears. These openings divide up the fluid stream and as the gears rotate away from the inlet port, the meter's inner wall closes off the chamber to hold the fixed amount of fluid.

The outlet port is located in the area where the gears are coming back together. The fluid is forced out of the meter as the gear teeth mesh and reduce the available pockets to nearly zero volume.

Helical gear [ ] Helical gear flow meters get their name from the shape of their gears or rotors. These rotors resemble the shape of a helix, which is a spiral-shaped structure. As the fluid flows through the meter, it enters the compartments in the rotors, causing the rotors to rotate. The length of the rotor is sufficient that the inlet and outlet are always separated from each other thus blocking a free flow of liquid. The mating helical rotors create a progressive cavity which opens to admit fluid, seals itself off and then opens up to the downstream side to release the fluid. This happens in a continuous fashion and the flowrate is calculated from the speed of rotation.

Nutating disk meter [ ] This is the most commonly used measurement system for measuring water supply in houses. The fluid, most commonly water, enters in one side of the meter and strikes the disk, which is eccentrically mounted. The disk must then 'wobble' or nutate about the vertical axis, since the bottom and the top of the disk remain in contact with the mounting chamber. A partition separates the inlet and outlet chambers. As the disk nutates, it gives direct indication of the volume of the liquid that has passed through the meter as volumetric flow is indicated by a gearing and register arrangement, which is connected to the disk. It is reliable for flow measurements within 1 percent. Variable area meter [ ] The, also commonly called a, consists of a tapered tube, typically made of glass, with a float inside that is pushed up by fluid flow and pulled down by gravity.

As flow rate increases, greater viscous and pressure forces on the float cause it to rise until it becomes stationary at a location in the tube that is wide enough for the forces to balance. Floats are made in many different shapes, with spheres and spherical ellipses being the most common.

Some are designed to spin visibly in the fluid stream to aid the user in determining whether the float is stuck or not. Rotameters are available for a wide range of liquids but are most commonly used with water or air.

They can be made to reliably measure flow down to 1% accuracy. Turbine flow meter [ ] The turbine flow meter (better described as an axial turbine) translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user-readable rate of flow (gpm, lpm, etc.). The turbine tends to have all the flow traveling around it.

The turbine wheel is set in the path of a fluid stream. The flowing fluid impinges on the turbine blades, imparting a force to the blade surface and setting the rotor in motion.

When a steady rotation speed has been reached, the speed is proportional to fluid velocity. Turbine flow meters are used for the measurement of natural gas and liquid flow. Turbine meters are less accurate than displacement and jet meters at low flow rates, but the measuring element does not occupy or severely restrict the entire path of flow. The flow direction is generally straight through the meter, allowing for higher flow rates and less pressure loss than displacement-type meters.

They are the meter of choice for large commercial users, fire protection, and as master meters for the water distribution system. Strainers are generally required to be installed in front of the meter to protect the measuring element from gravel or other debris that could enter the water distribution system. Turbine meters are generally available for 4 to 30 cm ( 1 1⁄ 2–12 in) or higher pipe sizes. Turbine meter bodies are commonly made of bronze, cast Iron, or ductile iron. Internal turbine elements can be plastic or non-corrosive metal alloys. They are accurate in normal working conditions but are greatly affected by the flow profile and fluid conditions.

Fire meters are a specialized type of turbine meter with approvals for the high flow rates required in fire protection systems. They are often approved by Underwriters Laboratories (UL) or Factory Mutual (FM) or similar authorities for use in fire protection.

Portable turbine meters may be temporarily installed to measure water used from a. The meters are normally made of aluminum to be lightweight, and are usually 7.5 cm (3 in) capacity. Water utilities often require them for measurement of water used in construction, pool filling, or where a permanent meter is not yet installed. Woltman meter [ ] The Woltman meter (invented by Reinhard Woltman in the 19th century) comprises a rotor with helical blades inserted axially in the flow, much like a ducted fan; it can be considered a type of turbine flow meter. They are commonly referred to as helix meters, and are popular at larger sizes. Single jet meter [ ] A single jet meter consists of a simple with radial vanes, impinged upon by a single jet.

They are increasing in popularity in the UK at larger sizes and are commonplace in the. Paddle wheel meter [ ] This is similar to the single jet meter, except that the is small with respect to the width of the pipe, and projects only partially into the flow, like the paddle wheel on a Mississippi riverboat. Multiple jet meter [ ] A multiple jet or multijet meter is a velocity type meter which has an impeller which rotates horizontally on a vertical shaft.

The impeller element is in a housing in which multiple inlet ports direct the fluid flow at the impeller causing it to rotate in a specific direction in proportion to the flow velocity. This meter works mechanically much like a single jet meter except that the ports direct the flow at the impeller equally from several points around the circumference of the element, not just one point; this minimizes uneven wear on the impeller and its shaft. Thus these types of meters are recommended to be installed horizontally with its roller index pointing skywards.

Pelton wheel [ ] The turbine (better described as a ) translates the mechanical action of the Pelton wheel rotating in the liquid flow around an axis into a user-readable rate of flow (gpm, lpm, etc.). The Pelton wheel tends to have all the flow traveling around it with the inlet flow focused on the blades by a jet. The original Pelton wheels were used for the and consisted of a radial flow turbine with 'reaction cups' which not only move with the force of the water on the face but return the flow in opposite direction using this change of fluid direction to further increase the of the. Current meter [ ].

A propeller-type current meter as used for hydroelectric turbine testing. Flow through a large such as used at a plant can be measured by averaging the flow velocity over the entire area.

Propeller-type current meters (similar to the purely mechanical, but now with electronic data acquisition) can be traversed over the area of the penstock and velocities averaged to calculate total flow. This may be on the order of hundreds of cubic meters per second. The flow must be kept steady during the traverse of the current meters.

Methods for testing hydroelectric turbines are given in standard 41. Such flow measurements are often commercially important when testing the efficiency of large turbines. Pressure-based meters [ ] There are several types of flow meter that rely on, either by measuring the differential pressure within a constriction, or by measuring and to derive the. Venturi meter [ ] A meter constricts the flow in some fashion, and measure the differential pressure before and within the constriction. This method is widely used to measure flow rate in the transmission of gas through, and has been used since times. The of Venturi meter ranges from 0.93 to 0.97.

The first large-scale Venturi meters to measure liquid flows were developed by who used them to measure small and large flows of water and wastewater beginning at the end of the 19th century. Orifice plate [ ] An is a plate with a hole through it, placed perpendicular to the flow; it constricts the flow, and measuring the pressure differential across the constriction gives the flow rate. It is basically a crude form of, but with higher energy losses. There are three type of orifice: concentric, eccentric, and segmental. Dall tube [ ] The Dall tube is a shortened version of a Venturi meter, with a lower pressure drop than an orifice plate. As with these flow meters the flow rate in a Dall tube is determined by measuring the pressure drop caused by restriction in the conduit.

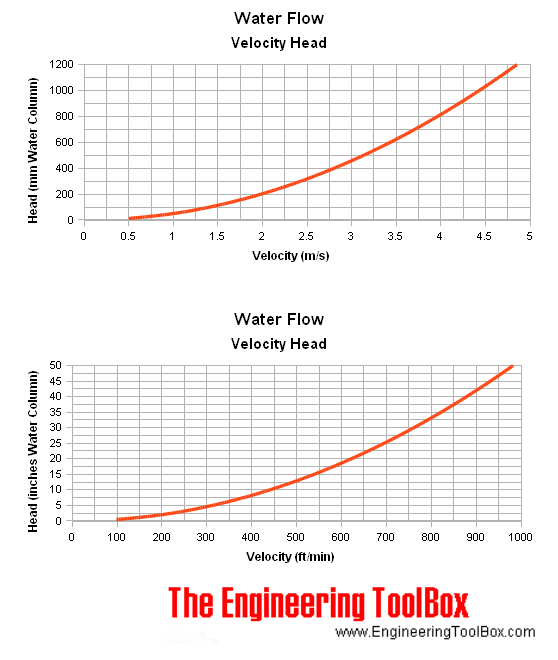

The pressure differential is typically measured using diaphragm pressure transducers with digital readout. Since these meters have significantly lower permanent pressure losses than orifice meters, Dall tubes are widely used for measuring the flow rate of large pipeworks. Differential pressure produced by a Dall tube is higher than Venturi tube and nozzle, all of them having same throat diameters. Pitot-tube [ ] A is a pressure measuring instrument used to measure fluid flow velocity by determining the and. While it is not suitable for measuring velocity in a turbulent flow, it determines the velocity profile by measuring the difference between total, static and dynamic pressure.

Used to calculate the dynamic pressure and hence fluid velocity. Multi-hole pressure probe [ ]. See also: Multi-hole pressure probes (also called impact probes) extend the theory of Pitot tube to more than one dimension. A typical impact probe consists of three or more holes (depending on the type of probe) on the measuring tip arranged in a specific pattern. More holes allow the instrument to measure the direction of the flow velocity in addition to its magnitude (after appropriate calibration).

Three holes arranged in a line allow the pressure probes to measure the velocity vector in two dimensions. Introduction of more holes, e.g.

Five holes arranged in a 'plus' formation, allow measurement of the three-dimensional velocity vector. Cone meters [ ].

8inch (200mm) V-cone flowmeter shown with ANSI 300# raised face Cone meters are a newer differential pressure metering device first launched in 1985 by McCrometer in Hemet, CA. The cone meter is a generic yet robust differential pressure (DP) meter that has shown to be resistant to effects of asymmetric and swirling flow. While working with the same basic principles as Venturi and orifice type DP meters, cone meters don’t require the same upstream and downstream piping. The cone acts as a conditioning device as well as a differential pressure producer. Upstream requirements are between 0–5 diameters compared to up to 44 diameters for an orifice plate or 22 diameters for a Venturi. Because cone meters are generally of welded construction, it is recommended they are always calibrated prior to service. Inevitably heat effects of welding cause distortions and other effects that prevent tabular data on discharge coefficients with respect to line size, beta ratio and operating Reynolds numbers from being collected and published.

Calibrated cone meters have an uncertainty up to +/-0.5%. Un-calibrated cone meters have an uncertainty of +/-5.0% [ ].

Linear resistance meters [ ] Linear resistance meters, also called laminar flow meters, measure very low flows at which the measured differential pressure is linearly proportional to the flow and to the fluid viscosity. Such flow is called viscous drag flow or laminar flow, as opposed to the turbulent flow measured by orifice plates, Venturis and other meters mentioned in this section, and is characterized by Reynolds numbers below 2000. The primary flow element may consist of a single long capillary tube, a bundle of such tubes, or a long porous plug; such low flows create small pressure differentials but longer flow elements create higher, more easily measured differentials. These flow meters are particularly sensitive to temperature changes affecting the fluid viscosity and the diameter of the flow element, as can be seen in the governing equation. Optical flow meters [ ]. Sonar flow meter on gas line flow meters are non-intrusive clamp on devices that measure flow in pipes conveying slurries, corrosive fluids, fluids and flows where insertion type flow meters are not desired. Sonar flow meters have been widely adopted in mining, metals processing, and upstream oil and gas industries where traditional technologies have certain limitations due to their tolerance to various flow regimes and turn down ratios.

Sonar flow meters have the capacity of measuring the velocity of liquids or gases non intrusively within the pipe and then leverage this velocity measurement into a flow rate by using the cross sectional area of the pipe and the line pressure and temperature. The principle behind this flow measurement is the use of underwater acoustics. In, to locate an object underwater, sonar uses two knowns: • The speed of sound propagation through the array (i.e. The sound speed of sea water) • The spacing between the sensors in the and then calculates the unknown: • The location (or angle) of the object. Likewise, sonar flow measurement uses the same techniques and algorithms employed in underwater acoustics, but applies them to flow measurement of oil and gas wells and flow lines. To measure flow velocity, sonar flow meters use two knowns: • The location (or angle) of the object, which is 0 degrees since the flow is moving along the pipe, which is aligned with the sensor array • The spacing between the sensors in the sensor array and then calculates the unknown: • The speed of propagation through the array (i.e. The flow velocity of the medium in the pipe).

Electromagnetic, ultrasonic and Coriolis flow meters [ ]. A magnetic flow meter at the in,. Modern innovations in the measurement of flow rate incorporate electronic devices that can correct for varying pressure and temperature (i.e. Density) conditions, non-linearities, and for the characteristics of the fluid.

Magnetic flow meters [ ], often called 'mag meter's or 'electromag's, use a applied to the metering tube, which results in a potential difference proportional to the flow velocity perpendicular to the lines. The potential difference is sensed by electrodes aligned perpendicular to the flow and the applied magnetic field.

The physical principle at work is of. The magnetic flow meter requires a conducting fluid and a nonconducting pipe liner. The electrodes must not corrode in contact with the process fluid; some magnetic flowmeters have auxiliary transducers installed to clean the electrodes in place. The applied magnetic field is pulsed, which allows the flowmeter to cancel out the effect of stray voltage in the piping system. Non-contact electromagnetic flow meters [ ] A system is called Lorentz force flowmeter (LFF).

A LFF measures the integrated or bulk Lorentz force resulting from the interaction between a in motion and an applied magnetic field. In this case the characteristic length of the magnetic field is of the same order of magnitude as the dimensions of the channel. It must be addressed that in the case where localized magnetic fields are used, it is possible to perform local velocity measurements and thus the term Lorentz force velocimeter is used. Ultrasonic flow meters (Doppler, transit time) [ ] There are two main types of: Doppler and transit time. While they both utilize ultrasound to make measurements and can be non-invasive (measure flow from outside the tube, pipe or vessel), they measure flow by very different methods.